Spindle Shaft

From Teamnumber1

Contents |

Spindle Shaft Design, 7th April

- Developed a model to predict the peak cutting force and shaft torque

- Wrote a matlab tool (edited version 12th April below) to determine peak forces and bending moments in spindle shaft and bearings

- Wrote a matlab tool to specify bearing from cutting force, torque, and desired life and reliability (via the Weibull Equation)

- Specified a collet from sheets provided in lab

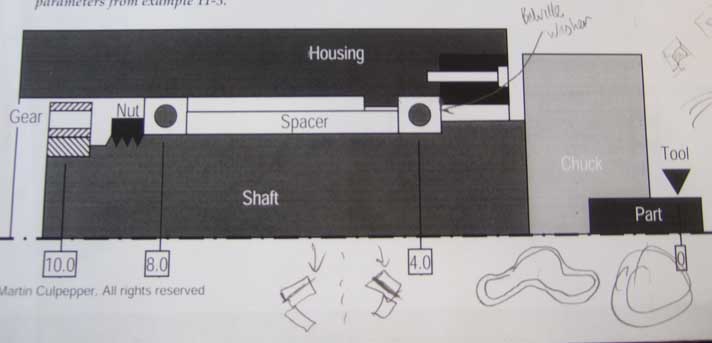

- Used results from above tools and supplied lathe solid model to specify shaft dimensions:

- 30 mm shaft outer diameter, 50mm diameter for center section

- 10 mm inner diameter

Spindle Shaft Design, 12th April

- Altered matlab tool to take into account fatigue at bearing A.

- For a steel shaft, we have a slope factor of safety of 9, a stress factor of safety of 15. The stresses are an order of magnitude below the endurance limit, so fatigue should not occur anywhere in this shaft. (or, a lifetime of 10^10 minutes - about right according to Chris).

- Assumptions - w_shaft = 570rpm, axial force = 100N, radial force = 240N, stress concentration at fillet = 2.5, assume 1020 steel which is pretty weak.

- Endurance limit of 1020 steel = 210MPa, k_overall=0.75, Von Mises stress at Bearing A = 21.6MPa, and smaller at nut by rough calculation.

Spindle Shaft Bearing Constraint

As discussed with Chris 4/26 - Martin & Ani

Bearing Selection

For spindle shaft bearings, we selected tapered roller bearings - see Bearing Selection for more details.