HP and Operational Management

From Lauraibm

Contents |

Summary

What the Vendor says about itself

HP Environment: Operational Management

In May 2006, we announced a new program of facilities consolidation. The HP Workplace Transformation program provides us the opportunity to improve our space utilization and install more energy-efficient equipment. Our goal is to reduce carbon dioxide emissions from HP owned and HP leased facilities worldwide to 15% below 2006 levels by 2010.

Our environmental, health and safety (EHS) management system helps us to identify, evaluate, control, manage and reduce environmental impacts in all our facilities. The system accommodates regular changes in our operations and ensures compliance with regulations and company standards. See Management system for more information.

Our environmental management also creates cost savings. In 2006, we saved $4.9 million dollars by recycling 87.3% of the solid waste generated from our large U.S. sites (compared to landfill or incineration costs). Our reuse program accounts for about 60% of the savings and recycling rebates provide the remaining 40%.

HP's most significant environmental aspects from operations and main focus areas have remained consistent for the last several years:

- Energy use

- Solid waste (nonhazardous and hazardous)

The other environmental aspects that we also monitor and manage are:

- Fossil fuel use for HP owned vehicles, business travel and employee commuting

- Water use in our facilities

- Chemical use in manufacturing (PFCs, air emissions, chemical releases) and facilities (ozone depleting substances)

Each year we analyze the main environmental aspects of our operations to determine which are the most significant and where we should prioritize our efforts. Our annual review focuses on:

- Significant changes to our operations, causing us to increase or decrease attention to environmental aspects

- Regional variations in our operations environmental impacts

- Trends in our environmental data

- Significant accidents or violations

- External views including issues raised by socially responsible investors

(1)

Climate

Governments, businesses and individuals must all play a role in reducing greenhouse gas (GHG) emissions that cause climate change. Increasingly, our customers and shareholders expect us to decrease our climate impact. Against a background of rising global energy prices, there is a strong business case for investing in energy efficient technology. HP continues to lead the IT industry in reducing the energy used by our operations and products.

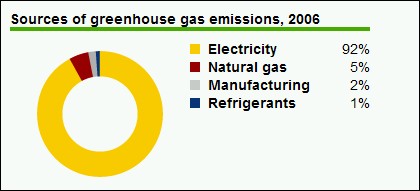

Greenhouse gas emissions HP's most significant source of greenhouse gas (GHG) emissions from operations is energy consumption, primarily electricity. Energy use accounts for 97% of our GHG emissions. Our environmental operations strategy focuses on consolidating our operations into core sites, with our HP Workplace Transformation initiative enabling us to improve space utilization and install more energy efficient equipment, in a phased approach over time. Our goal is to reduce energy consumption and the resulting carbon dioxide emissions from HP owned and HP leased facilities worldwide to 15% below 2006 levels, by 2010.

We are expanding our use of renewable energy, by purchasing green electricity and installing onsite generation at selected locations.

Performance Although our total energy use in operations decreased by 1% from 2005 to 2006, our 2006 emissions of greenhouse gases increased 3% or by 47,200 tonnes of CO2 equivalent. This is due to changes in the global energy mix for electricity generation. In April 2006, the World Business Council for Sustainable Development (WBCSD) and the World Resources Institute (WRI) updated its GHG Protocol emission factors for electricity generation, to reflect these changes. Using the old factors, HP's GHG emissions would have decreased 5%.

Emissions per unit of floor space increased 5% due to the changes in electricity conversion factors and a 2% reduction in floor space. Emissions per unit revenue, a measure of overall efficiency, decreased by 3%.

Perfluorocarbons Perfluorocarbons (PFCs) are gases used widely in the semiconductor industry for cleaning and etching processes. The global warming potential of PFCs ranges from 6,500 to 23,900 times greater than CO2.

In the United States, HP participates in the PFC Reduction Climate Partnership, a voluntary initiative with the U.S. Environmental Protection Agency (EPA) to reduce specified PFC emissions by 10% from 1995 levels by the end of 2010. In 2006, HP decreased its PFC emissions by 59% from 2005, to 34% below the 1995 level. Installing additional abatement technology at our manufacturing plants enabled us to meet the 2010 EPA goal in 20061. (2)

Waste

HP is committed to reducing waste generated by our global operations. Where possible, waste is eliminated at the source. Where this is not feasible, we aim to divert potential waste to beneficial uses. Disposal is a last resort, to be used when other waste management options are not reasonably available. Where disposal is necessary, HP's programs ensure wastes are managed in an environmentally responsible manner.

Hazardous waste Hazardous waste classification varies by country. HP data includes some wastes not considered hazardous in the country where generated.

In 2006, total hazardous waste disposed by HP site operations increased 23% compared to 2005. The largest volume of hazardous waste comes from the manufacturing and recycling of dilute ink waste, which increased due to increased production. The second largest category of hazardous waste material is solvents used in manufacturing, including n-methyl pyrrolidone, which we recycle. We also recycle off-specification inkjet cartridges from manufacturing.

We did not meet our target to reduce the amount of incinerated hazardous waste by 10%. The total amount incinerated increased by 3%. However, we reduced the percentage of hazardous waste disposed by incineration from 46% in 2005 to 39% in 2006.

Examples of hazardous waste reduction during 2006 include:

- Dublin, Ireland. Installed a nickel treatment process to treat nickel waste. In 2004 and 2005, the site sent a yearly average of 122 tonnes at a cost of $125,000 for incineration. By the end of 2006, the site had reduced the total waste on site by 9%, saving $35,000.

- Nashville, Tennessee. Diverted 132 tonnes of ink from incineration to reuse within an ink cartridge recycling and evaporation process, saving HP $50,000.

In 2007, we are expanding our audit program to identify additional solid waste reduction opportunities outside of the United States.

Total hazardous waste increased 23% in 2006 due mainly to increased production. We reduced the percentage of hazardous waste incinerated from 46% to 39% and the percentage sent to landfill was further reduced from 0.8% to 0.1%. The percentage recycled was increased from 10% to 11%.

(3)

Water

Although HP's operations are not water intensive, we recognize that water consumption is a growing concern, particularly in water-stressed regions. Our largest water use is for cooling.

Many of our sites work to reduce water consumption. Examples in 2006 include:

- United States. The Vancouver, Washington site implemented landscaping changes to use more native plants, converted to drip irrigation and reduced grass watering. These changes decreased landscaping water use by 50%.

- United States. The San Francisco Bay Area and Roseville, California sites implemented a computerized irrigation system, which adjusts irrigation schedules based on soil moisture content. We expect water savings of up to 30% in 2007.

HP global water consumption increased 3% in 2006, compared to 2005. Consumption in the Europe, Middle East and Africa region decreased 27%, primarily due to temperature decreases in those areas compared to the unusually hot 2005. Water use in the Americas and Asia Pacific and Japan regions increased by 6% and 12%, respectively, due to relocations and business growth.

(4)

Employee Travel

HP recognizes the impact on climate change of carbon dioxide (CO2) emissions that result from employee business air travel. Emissions have increased roughly in line with business growth.

Carbon dioxide emissions from employee business air travel, 2004-2006 [Tonnes CO2]

2004 = 253,000, 2005 = 270,000 and 2006 = 289,000

We encourage employees to use teleconferencing whenever possible, to reduce CO2 emissions from transportation and to cut costs. Employees frequently use web-based meetings and conference calls for training and collaboration. We provide several solutions, including the HP Virtual Room and the HP Halo Virtual Collaboration System.

HP owned cars and planes HP has a small number of aircraft and a fleet of company cars for sales and services employees. The aircraft represent a small portion of our total CO2 emissions from employee business travel. CO2 emissions from our U.S. and Canadian auto fleet totaled 89,400 tonnes CO2 in 2006. CO2 emissions from our Europe, Middle East and Africa auto fleet totaled 85,400 tonnes CO2 in 2006. We are expanding data collection to include our fleet in Asia Pacific and Japan.

Employee commuting

While CO2 emissions from employee commuting are not directly within HP's control, we have programs designed to reduce them. Our global Telework program allows employees to work from home whenever consistent with business needs.

We currently have nearly 13,000 employees worldwide who work exclusively from home offices. Approximately 10,400 of those employees work in the United States and Canada. We estimate that in 2006, the Telework program saved almost 2.5 million round-trip commutes, avoiding approximately 65 million miles of road travel and almost 28,000 tonnes of CO2 emissions. Other employees work at an HP site only a few days a week. We are considering how to calculate the CO2 savings for these employees as well.

(5)

Sources

- 2. Climate

- 3. Waste

- 4. Water