CanSat Launcher V2

From Dare

m |

m |

||

| Line 1: | Line 1: | ||

| - | DARE was invited for the [http://edu2.zfw.etc.tu-bs.de/stec/index.htm|Space | + | DARE was invited for the [http://edu2.zfw.etc.tu-bs.de/stec/index.htm|Space Technology Education Conference 2006] by ESA in Braunschweich, Germany.. On STEC 2006 DARE planed to launch a CanSat Launcher. Unfortunately CanSat Launcher V1 crashed on the 28th of April and STEC 2006 began on the 9th of may. This led to heavy time pressure to redesign and build the next version of the CanSat Launcher. |

[[Image:STEClogo.jpg|frame|centre|dont float|Space Technologie Education Conference logo]] | [[Image:STEClogo.jpg|frame|centre|dont float|Space Technologie Education Conference logo]] | ||

== The design and build == | == The design and build == | ||

Current revision as of 12:54, 23 June 2007

DARE was invited for the Technology Education Conference 2006 by ESA in Braunschweich, Germany.. On STEC 2006 DARE planed to launch a CanSat Launcher. Unfortunately CanSat Launcher V1 crashed on the 28th of April and STEC 2006 began on the 9th of may. This led to heavy time pressure to redesign and build the next version of the CanSat Launcher.

Contents |

The design and build

The most inportant choises

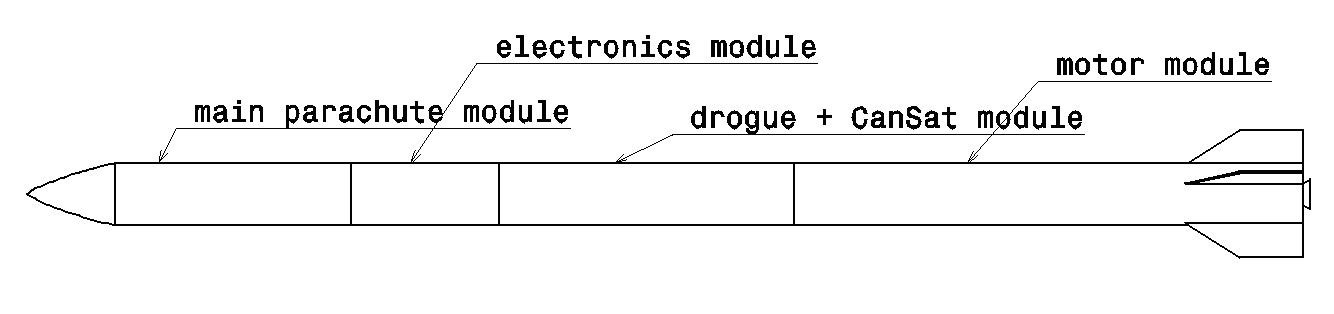

The CanSat launcher is module based. A module-based rocket may be heavier and/or more complex but is easier to upgrade and repair. The CanSat Launcher doesn’t have to break altitude records but has to be reliable and fly multiple times a day. Currently the CanSat launcher has four modules but this can be changed in the future depending on the mission. From bottom to top the modules are: motor module, CanSat and drogue module, electronics module and main parachute module.

The design of the CanSat Launcher is based on two fixed parameters, the size of a soda can and the size of the motor. A third important parameter is the size of an adult hand because it is very useful to be able to insert your hand into the rocket body to tighten a nut for example. This leads to an inner diameter of 100 mm. The second important choice is how the CanSat should be released. In short there are three options. One: separate the rocket in the middle and deploy the main parachute with the same action, the CanSat will slide out the top part of the rocket. The Americans use this option. Two: Deploy the Main parachute and your drogue either by separation or push it out the top. Let a third mechanism release the CanSat sideways. Three: Separate your rocket in the middle and push the CanSat and your drogue out in one action. Deploy the main parachute at the top. The CanSat Launcher uses the third option because in the Netherlands it is obligatory to use a two-stage recovery system when apogee is higher then one kilometre. By using option three only two actions are needed to release the CanSat and deploy both the drogue and main parachute. A second advantage is that the CanSat is almost at the centre of gravity and thus has little influence on the stability of the rocket. The last important choice is the size of the fins. We use a simulation program called RockSim to calculate the size of the fins.

The hull

The hull of the rocket is made of glass fibre reinforced plastic (GFRP). The process to manufacture this is still being improved. The hull of this rocket is made in the following way: a plastic sheet is wrapped around a PVC tube to make the hull come of easily when hardened. When the mould is ready, a glass fibre mat is filled with epoxy. The mat is wrapped around the tube and aluminium rings are place around the GFRP to strengthen the places where a bolt connection is needed. A second layer of glass fibre with epoxy is wrapped around the tube. The final step is to wrap a plastic sheet around the hull to give it a smooth finish.

The motor module

The motor module has two functions, to deliver thrust and stability. The dx1-ee motor generates the thrust. This motor is in-house developed and is the successor of the dx1 motor (another DARE creation). The dx1-ee is a solid propellant motor made of stainless steel with a convergent-divergent nozzle. It works on a mixture of KNO3 and sorbitol and is estimated to deliver a total impulse somewhere between 2000 and 2500 Ns. To stabilise the rocket fins are attached to the motor module. The fins are made of triplex and GFRP. The fins are attached to the hull in two steps. First the triplex fins are glued on the hull. The second step is to laminate them with glass fibre and epoxy. In this way the fins are stiff and firmly attached to the hull. On top of the motor module is the CanSat canister.

The CanSat and drogue module

This module holds the CanSat and drogue. At apogee a pyrocharge is triggered. The gasses of this charge push out the drogue and the CanSat canister. The canister will open and the drogue will deploy. The canister is made of the same PVC tube as the mold. This gives a very tight sealing, which readily slides. In the canister there is a spring which pushes the cansat out of the canister when the canister is no longer inside the rocket hull. The drogue is a cross parachute. This shape is chosen because it easier to produce than a spherical parachute. The drogue will decelerate the speed of the rocket to 20 m/s.

The electronics module

The function of the electronics module is to gather in-flight data and based on that trigger the pyrocharges. It also functions as a beacon. To do this two different sets of rocket electronics are used. The first one is the R-das from AED. This piece of equipment measures static pressure and G-forces. It can trigger at apogee (based on its accelerometer), altitude and time. The second piece of equipment is the in-house developed MicroDAREdas V2.0. This one has two pressure sensors. It can trigger at apogee (based on pressures), altitude and time. It can also send telemetry which doubles as a locating beacon. Both pieces of equipment have onboard storage. Although two different sets of electronics is heavier it will improve the reliability. That’s why they both have their own power supply and their own set of pyrocharges. On top of the electronics module are the pyrocharges to deploy the main parachute.

The main parachute module

This module simply holds the main parachute. This cross parachute decelerates the rocket to 7 m/s. On top of this module is the nosecone.

The flight

At t=0 an igniter will start the motor. After 1.4 seconds the boost phase ends and the rocket will start coasting to apogee. At apogee (around 1200m) the electronics will blast the CanSat canister and the drogue out the rocket. The CanSat will leave the canister and follow its own path. The rocket will decelerate to 20 m/s. At 200 m the electronics will ignite the main parachute charge. The main parachute will leave the rocket through the top and decelerate the rocket to 7 m/s.

The launch

This rocket was launched on a military base near Braunschweig. Weather conditions were good on this day. Visibility was very good, cloud base high. Wind speed was 5-10 kts, blowing from the north. Ignition went well, the rocket left the tower at a normal velocity (estimated: 30 m/s).The rocket reached its simulated altitude of 1.2 km and probably went even higher. The telemetry of the rocket did not work as well as it had to, because of interference with the CanSat, but the status of the rocket could be extracted from the acoustic reproduction of the transmitted data. At apogee, from the telemetry of the launcher it could be deduced that the igniters, that had to initiate the deployment of the parachute and the release of the CanSat, were activated. After this, both the telemetry of the launcher and that of the CanSat went silent. No parachute deployment was observed, and the rocket must have crashed (although this was not seen). Only the nose cone has been recovered, the remainder of the rocket is only found a few months later.

What went wrong

The possibility of the electronics not detecting lift-off was substantially reduced by using break wires (wires that break during lift-off; thereby triggering the electronics) instead of a G-switch. Also a back-up electronics system was used (Micro dare-das V2.0). The rocket also reported its status to the ground station by a transmitter. The electric module performed perfectly during flight, until the rocket reached apogee. There, after triggering of the igniters, the launcher’s telemetry as well as that of the cansat stopped sending data. This is likely to be caused by the pyrotechnics blowing up the entire parachute and payload bay. How this could happen can be explained in the following way: The plunger in Prototype V1.0, which was formed by the payload bay, was not as airtight as the one used in V2.0. This caused the pressure in the second prototype to get higher than in the previous prototype, leading to the almost simultaneous ignition of both pyrotechnic charges, which was not as intended (the second charge was a backup charge). This combined ignition probably rendered the electronic components in the rocket and the cansat inoperative and is also likely to have shattered part of the rocket. Another possible failure cause is that the plunger got stuck in the outer tube, forcing the pressure to find another way out. The rocket’s structure could not withstand the pressure loads and broke up, thereby damaging the electronics, parachute and cansat. It is further noted that the right amount of black powder was not determined, because of a lack of building and testing time. Therefore, the charge in one igniter could have been too high. However, this failure is considered to be unlikely since there is a fair amount of experience present within DARE concerning black powder.