Fujitsu Group: Productive Activity that considers the Environment

From Lauraibm

Contents |

MI Summary

Fujitsu Group: Productive Activity that considers the Environment

Another Fujitsu document that smells as if it's been translated from Japanese. Focusses on the reduction of waste, chemical pollutants and the totla elimination of ozone-depleting substances.

Text of Article

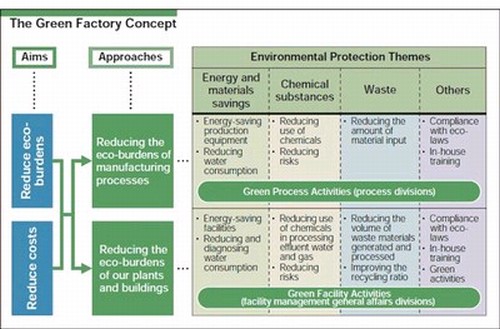

To reduce the burden imposed on the environment by the use of resources and energy at our factories and in our business activities, we are actively promoting the reduction of waste and chemical emissions and energy conservation measures.

As a means of promoting these environmental burden reduction measures, Fujitsu implements a range of Green Process and Green Facility activities. Our business activities are rooted firmly in strict observance of relevant laws and regulations; we also take a comprehensive approach to eliminating environmental risk before it occurs.

Green Process Activities

While reducing the costs of our production processes, we have set numerical targets for reducing the environmental burden of each production line (resource consumption, chemical use, energy consumption, and so on). We are continuously working to reduce our figures in these areas as much as possible.

Green Facility Activities

To ensure stable factory operations and reductions in the environmental burden, we are making improvements to our infrastructure, pursuing thorough environmental compliance, seeking to eliminate environmental risk, and working to reduce consumption levels for energy, water, and chemicals.

Waste Generation Reduction

The Fujitsu Group takes the "3R" concept—reducing, reusing, and recycling—as a fundamental principle for its business activities. With our eye on the achievement of a true recycling society, we are seeking to take our 3R activities to a higher level by promoting this approach among all our employees.

Waste Generation Reduction: Moves to reduce waste (excluding recoverables) generated through business activities.

Chemical Pollutant Reduction

The four Fujitsu production facilities, six consolidated manufacturing subsidiaries in Japan, and two consolidated manufacturing subsidiaries overseas use large amounts of chemical substances. These production sites have created usage reduction plans for 354 Class 1 substances identified in the PRTR Law*.

To help the facilities achieve the targets in these plans, chemical emissions reduction working groups gather twice a year to confirm levels of emissions and investigate problems. As part of efforts to meet chemical-reduction targets, we carefully maintain equipment used to handle gas and water effluent and undertake Green Process activities to standardize chemical usage and reduce the volume discharged.

- The PRTR Law identifies chemical substances that are subject to the Pollutant Release and Transfer Register and defines reporting requirements concerning their emission.

Total elimination of ozone layer depletion substances

We have completely eliminated the use of substances that contribute to depletion of the ozone layer in our manufacturing operations(parts cleaners and solvents). We have also taken measures to ensure that no CFC coolants used in air-conditioning or refrigeration equipment leak into the atmosphere. When renovating such equipment, we take the opportunity to replace the coolants with non-CFC alternatives.