HP: Waste

From Lauraibm

Contents |

MI Summary

Text of Article

HP is committed to reducing waste generated by our global operations. Where possible, waste is eliminated at the source. Where this is not feasible, we aim to divert potential waste to beneficial uses. Disposal is a last resort, to be used when other waste management options are not reasonably available. Where disposal is necessary, HP's programs ensure wastes are managed in an environmentally responsible manner.

Hazardous waste

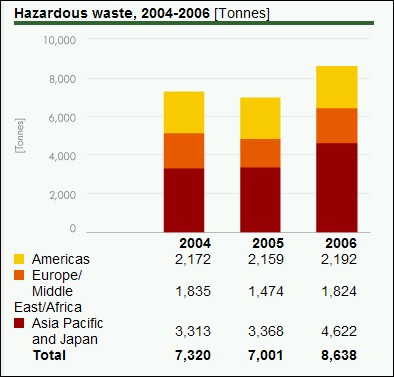

Hazardous waste classification varies by country. HP data includes some wastes not considered hazardous in the country where generated.

In 2006, total hazardous waste disposed by HP site operations increased 23% compared to 2005. The largest volume of hazardous waste comes from the manufacturing and recycling of dilute ink waste, which increased due to increased production. The second largest category of hazardous waste material is solvents used in manufacturing, including n-methyl pyrrolidone, which we recycle. We also recycle off-specification inkjet cartridges from manufacturing.

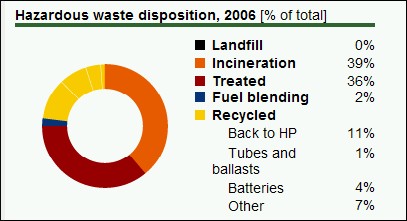

We did not meet our target to reduce the amount of incinerated hazardous waste by 10%. The total amount incinerated increased by 3%. However, we reduced the percentage of hazardous waste disposed by incineration from 46% in 2005 to 39% in 2006.

Examples of hazardous waste reduction during 2006 include:

- Dublin, Ireland. Installed a nickel treatment process to treat nickel waste. In 2004 and 2005, the site sent a yearly average of 122 tonnes at a cost of $125,000 for incineration. By the end of 2006, the site had reduced the total waste on site by 9%, saving $35,000.

- Nashville, Tennessee. Diverted 132 tonnes of ink from incineration to reuse within an ink cartridge recycling and evaporation process, saving HP $50,000.

In 2007, we are expanding our audit program to identify additional solid waste reduction opportunities outside of the United States.

Total hazardous waste increased 23% in 2006 due mainly to increased production. We reduced the percentage of hazardous waste incinerated from 46% to 39% and the percentage sent to landfill was further reduced from 0.8% to 0.1%. The percentage recycled was increased from 10% to 11%.

Non-hazardous waste

Non-hazardous waste remains a key focus at HP with targeted initiatives and widespread employee participation to reduce waste volumes.

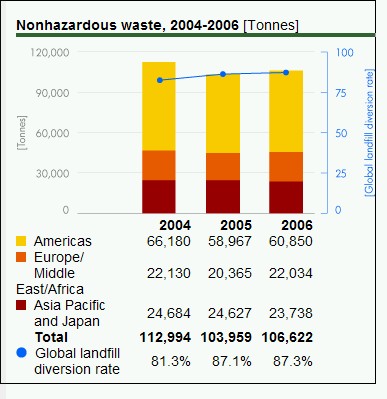

Total nonhazardous waste increased by 3% during 2006, partly due to site consolidation that generates waste when buildings are vacated. Even with this increase, we raised the global landfill diversion rate slightly from 87.1% in 2005 to 87.3% in 2006. Our target is to maintain an 87% landfill diversion rate globally through the end of 2007. We are continuing to improve separation of waste materials at our largest sites and pursue markets for recycled materials.

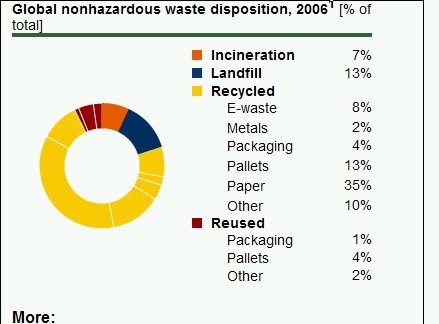

Our recycling program created $4.9 million of benefits for HP in 2006. Approximately 60% of this saving comes from reusing items and avoiding landfill costs and approximately 40% is the revenue from selling recycled materials.

HP facilities globally sponsor e-waste collection efforts. In 2006, 100 sites in Canada, Latin America and the United States celebrated Earth Day, which included employee home computer take-back campaigns at 70 sites. Employees recycled approximately 128,000 pounds of personal IT equipment through these events.

Total nonhazardous waste increased 3% in 2006. The global landfill diversion rate increased from 87.1% in 2005 to 87.3% in 2006. The highest volume waste streams are paper and pallets. These waste streams are also the largest waste streams diverted from landfill.

(3)

Source

- 3. Waste