Boots Group PLC

From Lauraibm

(→Waste and Recycling) |

(→Waste and Recycling) |

||

| Line 87: | Line 87: | ||

'''The waste issue''' | '''The waste issue''' | ||

Over recent years the management of waste has become increasingly complex and costly. New legislation for landfill, hazardous waste, waste electrical and electronic equipment, and changes to the packaging regulations continue to stretch business costs and environmental compliance. | Over recent years the management of waste has become increasingly complex and costly. New legislation for landfill, hazardous waste, waste electrical and electronic equipment, and changes to the packaging regulations continue to stretch business costs and environmental compliance. | ||

| + | |||

| + | '''What we are doing''' | ||

| + | For many years Boots has been a leader in the management of waste and recycling activities within the retail sector, and has a sound record in waste minimisation that has placed us in a good position for dealing with new legislative requirements. | ||

| + | |||

| + | We have operated a recycling facility on our head office site for the last 50 years. The current facility receives paper and board, soft mixed plastic, glass bottles, printer toner cartridges and 35 mm film pots | ||

| + | from our head office site and our stores. "Single use" cameras and film off-cuts are also recycled. | ||

| + | |||

| + | Over 23,000 tonnes of materials are collected, sorted and sent for recycling each year. | ||

| + | |||

| + | Within our Nottingham warehouses we recover cardboard boxes both for re-use within our business, and for re-use by external businesses. Cardboard supports on pallets are re-used in our manufacturing facilities and plastic wrapping from suppliers is re-used to protect some of our bottled pharmacy medicines sent to stores. | ||

| + | |||

| + | Within our stores we return plastic merchandising trays, used to display our chilled food offer, to our food supplier for re-use. | ||

| + | |||

| + | We use robust, re-usable containers for internal stock movements. The system has been in operation since the 1950s; currently over 700,000 containers each make over 50 trips a year. | ||

==Sources== | ==Sources== | ||

Revision as of 12:25, 17 July 2007

Contents |

Environmental Policy

We've been in business for over a hundred years and in that time we've built a reputation for caring about our customers, our people and the communities we work in around the world. Caring for the environment has always been an integral part of this and it's one of the core values of our brand.

We've looked at how each aspect of our business affects the environment and we've drawn up a list of priorities and areas where we'll commit our efforts.

Products and services We'll minimise the impact of our products and services by making our designs as efficient as possible, by taking account of specific issues like our use of chemicals and biodiversity, and by working closely with our suppliers.

Global warming We'll reduce both direct and indirect carbon emissions from the energy we use in buildings, transport and manufacturing operations.

Waste minimisation We'll make the best use of resources, particularly in areas like packaging, water efficiency and recycling.

Communication We'll encourage open discussion on the issues affecting us by talking and listening to our customers and other stakeholders, providing environmental information with our products and publicly reporting how we perform on our environmental policy.

For us, environmental management goes far beyond just obeying local legislation and preventing pollution. We strongly believe that good environmental practice is good for business, a fundamental corporate responsibility and a key contributor to sustainable development. All our people, suppliers and contractors have a valuable role to play by implementing this policy within their everyday activities. Putting environmental considerations at the heart of what we do ensures we manage them properly alongside other important business considerations such as safety, quality and value.

In order to make sure we continue to improve in environmental management, we'll set objectives and targets for the activities where we significantly affect the environment. We'll measure our performance on these over time and report our progress at least once a year.

Working in this way, we're sure we can continue to build on the ideals and principles that have distinguished Boots since the days of Jesse Boot.

(1)

Energy and Climate Change

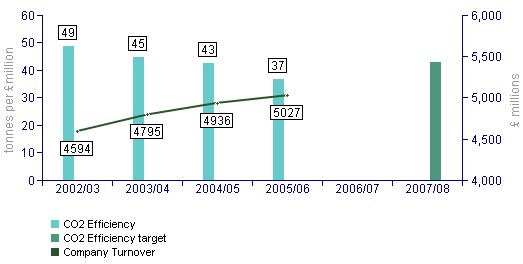

Reduce like-for-like carbon dioxide emissions by 10% Including adjustments for business changes since the original target was set in 2001, we reduced like-for-like carbon dioxide emissions by 22.9%, achieving 37 tonnes per £million turnover against our target of 43.2 tonnes per £million turnover. Our performance was partially helped by our purchase of combined heat and power electricity for our stores. We aim to continue further improving like-for-like efficiency by around 2% per annum.

Ever since we built our first combined heat and power plant in 1915, Boots has been prominent in the field of energy efficiency. As fuel bills continued to rise at an increasing rate in 2005/06, improving our performance in this area still further became an urgent business priority, as well as a pressing environmental concern.

Focusing on better carbon management We believe that reducing our energy use, and relentlessly seeking to eliminate waste, is by far the most effective way in which we can pursue both our environmental and commercial objectives.

Targeting a 10% head office reduction At our main site in Nottingham, we've set ourselves a target of reducing energy consumption by 10% over the next three years. We already benefit from efficient electricity and heat provision. In 1996, we invested £19 million in an advanced modern day equivalent of our original combined heat and power plant (CHP). Today, this enables us to generate around 90% of all the power we need on our 300 acre site, and around 80% of the heat. The efficiency of our CHP and its exceptionally good operation was recognised in 2005/06 by the award of ISO 14001 accreditation. Over the last year, we took effective steps to tackle energy wastage and bad practice in our office buildings and warehouses, such as ensuring that heating and air conditioning are not in use at weekends and that lights are not left on at night.

A shopping list of energy efficiency measures In 2002, we started working with the Carbon Trust to find ways of making our stores more energy efficient. Having completed this investigative phase, we moved into implementation mode in 2005/06. Among a wide range of measures, we invested around £500,000 to facilitate effective control of energy use through simple but effective system and wiring reconfiguration. This ensures that the correct equipment is being used in stores at the correct times. We have remote metering in 500 of our stores (380 more than legally required with around a further 200 to be installed during 2006/07), enabling us to identify and rectify excessive energy use. And for around 10% of our stores so far, we have installed building energy management systems, giving us complete real-time control over every aspect of their energy use.

Getting our people on board Modern technology can play a vital part in improved energy-efficiency, but we are very clear that people can also make a big difference. And, following on from a trial in our Western region, we will appoint regional Energy Champions right across our business, to keep an eye on energy use at 'grass roots' level, watch out for waste and, when necessary, have a quiet word with colleagues. We've recently held an energy efficient road-show at our head office. And, because we know that good energy habits begin at home, we will be giving useful cost and energy saving tips to all our people.

Targeting a £2-3 million annual saving Over the next three years, we'll be investing over £5 million in continuing to improve our energy efficiency, with the aim of achieving annual savings of £2-3 million, and further reducing our carbon dioxide emissions by over 8000 tonnes.

Renewable Energy Currently, just 1% of all the power Boots uses comes from renewable sources. In 2003 we set a target to achieve 6% by 2007/08. As we have mentioned, our concerns about the authenticity and verification of some renewable energy sources are only just beginning to be addressed, and obtaining a sufficient supply at commercially realistic prices remains difficult to guarantee. We continue to review carefully all the possibilities in this area, alongside continuing to drive energy efficiency.

In the mean time, around 90% of the electricity used in our stores, and the vast majority used on our head office site, comes from extremely efficient and more 'environmentally friendly' combined heat and power sources. The proportion of CHP electricity in our stores will increase to around 95% in 2006/07.

Sharing ideas about saving power During 2005/06, Boots was instrumental in the foundation of the Retail Energy Forum, a new grouping of energy specialists from many of the UK's top retailers, who will meet regularly to share ideas and best practice. Boots also belongs to the CBI's energy policy committee, the British Retail Consortium's energy forum and the Combined Heat and Power Association. More recently, our group energy manager has been seconded to the Sustainable Energy Policy Division of DEFRA to help provide a strategic overview of their policies in promoting energy efficiency and carbon reduction to the commercial sector.

Our healthy store project Like a number of other major retailers, we are currently working to develop 'the store of the future'; a branch of Boots that will reach new levels of energy-efficiency and all round environmental responsibility. We're very clear that our aim is not to indulge in blue-sky thinking, but to develop and test practical ideas which we will be able to roll out and replicate throughout our 1,500 stores, over the next few years.

We're also keen to look beyond environmental impact. Our healthy store project, though still at an early stage, is equally concerned with providing better working conditions for our people and the necessary facilities for developing Boots role in delivering community healthcare services. We'll be reporting on our progress.

(2)

Waste and Recycling

Performance Summary 2005/06 The percentage of total waste sent to landfill has reduced from 54% in 2002/03 to 46.6% in 2005/06.

Historical data has been adjusted to reflect the sale of Boots Healthcare International in January 2006 to maintain the integrity of historical trends.

Boots Retail and Facilities Management Total waste increased this year by 679 tonnes to 40,052 tonnes. However, trends within the waste hierarchy during 2005/06 were:

- Recycling increased by 1,801 tonnes

- Charitable donations increased by 138 tonnes

- Incineration with heat recovery increased by 317 tonnes

- Incineration without heat recovery reduced by 8 tonnes and

- Landfill reduced by 1,431 tonnes

Boots Manufacturing Total waste increased by around 280 tonnes (5%) despite manufacturing output increasing by 7%.

Trendswithin the waste hierarchy during 2005/06 were:

- Recycling increased by 315 tonnes

- Composting reduced by 150 tonnes

- Incineration with heat recovery reduced by 290 tonnes

- Incineration without heat recovery increased by 153 tonnes and

- Landfill increased by 250 tonnes.

The waste issue Over recent years the management of waste has become increasingly complex and costly. New legislation for landfill, hazardous waste, waste electrical and electronic equipment, and changes to the packaging regulations continue to stretch business costs and environmental compliance.

What we are doing For many years Boots has been a leader in the management of waste and recycling activities within the retail sector, and has a sound record in waste minimisation that has placed us in a good position for dealing with new legislative requirements.

We have operated a recycling facility on our head office site for the last 50 years. The current facility receives paper and board, soft mixed plastic, glass bottles, printer toner cartridges and 35 mm film pots from our head office site and our stores. "Single use" cameras and film off-cuts are also recycled.

Over 23,000 tonnes of materials are collected, sorted and sent for recycling each year.

Within our Nottingham warehouses we recover cardboard boxes both for re-use within our business, and for re-use by external businesses. Cardboard supports on pallets are re-used in our manufacturing facilities and plastic wrapping from suppliers is re-used to protect some of our bottled pharmacy medicines sent to stores.

Within our stores we return plastic merchandising trays, used to display our chilled food offer, to our food supplier for re-use.

We use robust, re-usable containers for internal stock movements. The system has been in operation since the 1950s; currently over 700,000 containers each make over 50 trips a year.